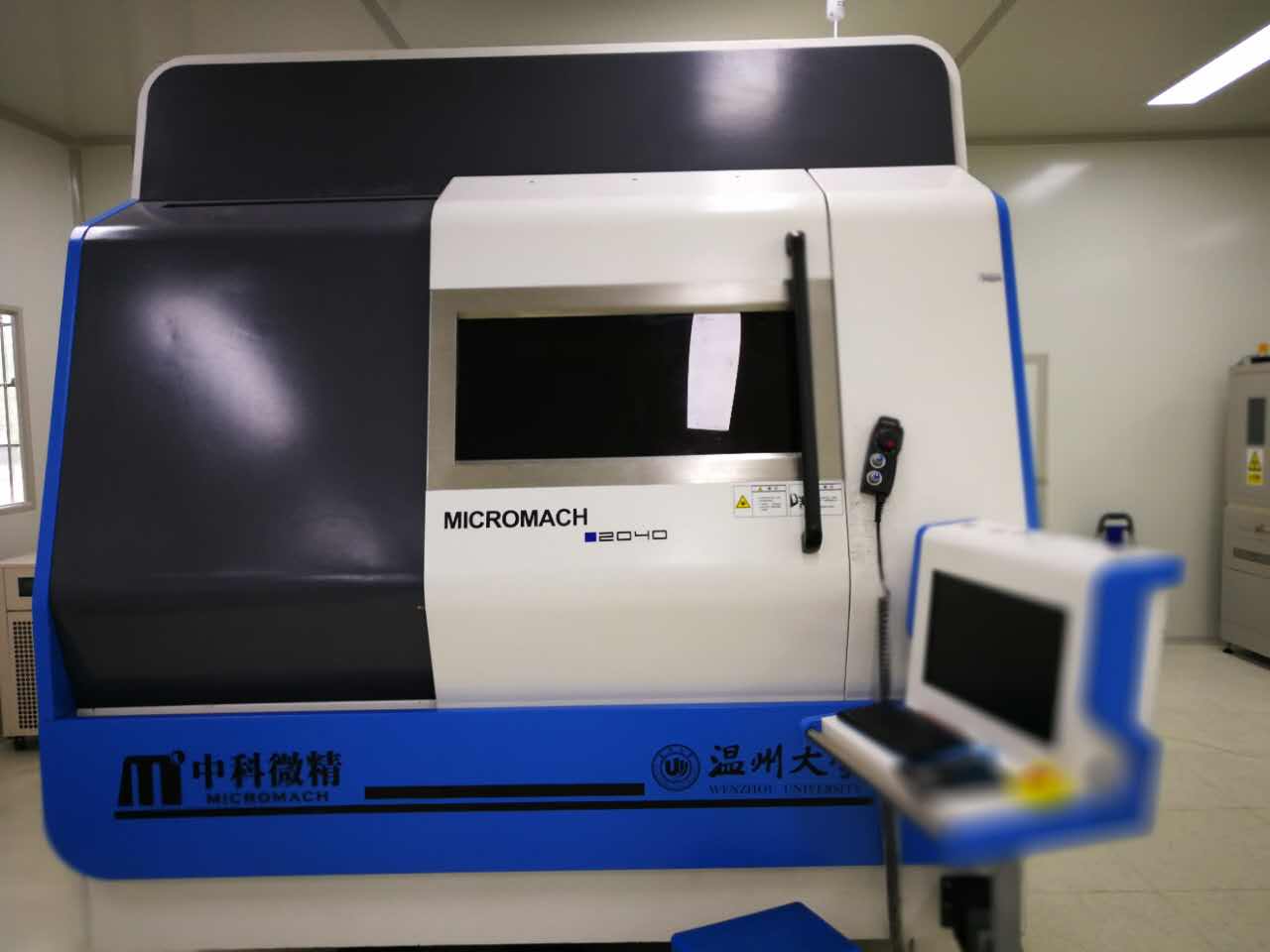

Instrument Name:Laser micro-machining system.

Serial number for instruments:20164485

specifications and models:MICROMACH 2040

Date of purchase:2015/12/12

Parameters:

1. laser system:

Output wavelength: 980-1070nm;; Average output power: 215W@100KHZ;; Pulse width: less than 15PS;; Maximum single pulse energy: > 0.1mJ;; Beam quantity: M2<1.3.

Pulse stability: < 1% rms; Repetition frequency: The repetition frequency is 200-1000KHz, which can realize single pulse output.

2. Frequency doubling output optical path system:Harmonic conversion efficiency: 50%(SH),25%(TH).

3. Monitoring and detection system of machining process:Coaxial/paraxial (CCD) camera image system has the function of self-adaptive adjustment of focal length, and the magnification of visual unit is adjustable from 10x to 500x.

4. Design of drilling (rotary cutting) optical module:The minimum focal spot is < 15~3um, and the minimum machining aperture is ≤10um; Adjustable drilling taper.

Rotating speed of optical rotary cutting system is 3000 rpm.

5. Design of 3D scanning galvanometer module:Galvanometer index: scanning speed: more than 3m/s.

Resolution: ≤ l5urad; Accuracy of repeated positioning: ≤ 25urad; Entrance aperture: ≥ 29mm; Scanning angle; ±0.35rad

The field mirror index: f = 63mm/100mm/163mm/254mm;

Functions:The experimental platform is equipped with ultrafast laser system, double frequency/triple frequency system, beam shaping system, coaxial (CCD) camera monitoring system, drilling optical module, cutting head and rotary cutting optical module, scanning galvanometer module, multi-beam parallel processing module, numerical control mobile system and software control system, which can realize cutting head processing, rotary cutting processing, three-dimensional galvanometer scanning processing and multi-beam parallel processing of ultrafast lasers with fundamental frequency, double frequency and triple frequency. Equipped with a monitoring and detection system for machining process, it can realize high-precision positioning, on-line tracking by CCD camera, detection and monitoring, etc. Equipped with high-precision positioning workbench system, it can prepare straight holes, inclined holes, stepped holes, tapered holes, irregular holes, micro-nano structures and bionic surfaces on the plane, inclined surfaces and curved surfaces of solid materials (semiconductor materials, glass materials, metal materials, ceramic materials, polymer materials, non-metallic materials, etc.) and liquid materials (gel, metal ion aqueous solution, optical resin and other organic solutions).