Recently, Dr. Yanhu Wang (first author) and Prof. Xizhang Chen (corresponding author) from the International Cooperation Base for Laser Processing Robotics of our university, in cooperation with Siberian State Technical University, published a research paper entitled "Research on plasma arc additive manufacturing of Inconel 625 Ni-Cu" in the top international journal Materials Science and Engineering: A The research paper entitled "Research on plasma arc additive manufacturing of Inconel 625 Ni-Cu functionally graded materials" was published in the top international journal Materials Science and Engineering: A.

Functional gradient materials have developed rapidly in recent years and have great potential for applications in aerospace, biomedical engineering, sensors, and energy. However, there are currently two major classes of functional gradient materials: thin films/coatings and bulk. Currently, with the diversification of society, functional gradient materials with complex geometries are highly sought after, yet traditional methods are difficult to prepare and often produce porosity, which reduces product quality and increases costs. Additive manufacturing, however, as an emerging technology, provides an effective way to address the drawbacks of traditional methods. It offers the potential for local control of composition and microstructure, and can produce complex functional gradient materials with multidimensional and directional gradient structures.

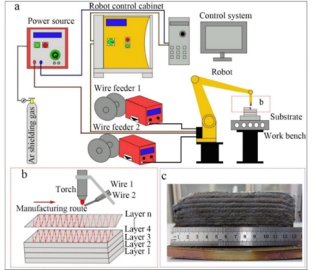

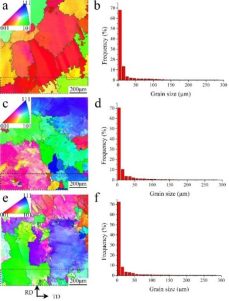

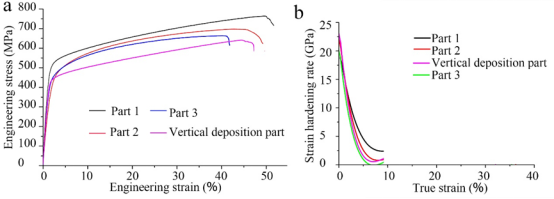

In this paper, we use the currently established Inconel 625 wire and pure copper (99.9%) solder wire as raw materials and use the plasma arc as a heat source to change the composition in the alloy by adjusting the wire feeding speed, thus preparing functional gradient materials with continuously changing composition and changing functional gradients. In particular, this paper utilizes the high growth limiting factor Q effect of copper to overcome the columnar crystal defects inherent in the additive manufacturing process, which opens the door to additive manufacturing and lays the foundation for the preparation of complex functional gradient components at low cost.