Recently, the key project supported by the National Natural Science Foundation of China, "Research on Key Technologies of Ultra-fast Laser Machining Superhydrophobic Complex Components for Offshore Equipment" (ProjectNo.), chaired by Professor Xue Wei from the Laser Base of Wenzhou University, was successfully completed. The completion of this project can improve the significant economic damage and potential safety hazards caused by seawater corrosion and marine organism attachment, and will provide an important enabling technical support for the comprehensive strengthening of China's offshore equipment manufacturing industry in the next 10 years. This project was jointly funded by the key project supported by the Joint Fund of National Natural Science Foundation of China, namely, the integration of two industries in Zhejiang.

In the fields of offshore engineering, aerospace, energy and power, high-speed rail locomotives, etc., many key components, such as aircraft wings and fuselage, marine propellers, turbine impellers, etc., are designed as spatially complex curved surfaces. How to precisely machine conformal functional microstructures on the surfaces of these complex curved parts is a key scientific and technological problem that urgently needs to be solved in the research and development of high-end manufacturing technology and equipment in China. Offshore equipment is a traditional advantageous industry in Zhejiang Province, and it is also one of the ten key development fields of "Made in China 2025". Seawater corrosion and attachment of marine organisms are chronic diseases of various offshore equipment, such as ships, offshore oil and gas resources development equipment, offshore floating structures, etc., which cause significant economic damage and potential safety hazards.

In this project, the key technologies of ultra-fast laser processing of super-hydrophobic surfaces of typical metal complex components of offshore equipment are studied, aiming at the requirements of anti-biofouling, drag reduction and noise reduction of various offshore equipment such as offshore ships, oil and gas resources development equipment and offshore floating structures. The so-called "super-hydrophobic surface" is to realize the "lotus leaf effect" on the metal surface, which requires laser micro-carving at a place thinner than the hair, and cutting tens or even hundreds of micron-sized or nano-sized "hills" on the metal surface with laser, so that its surface structure is similar to lotus leaf, which helps to lock the air and prevent water from wetting the surface. This superhydrophobic surface can effectively prevent pollution by sewage, thus realizing "self-cleaning" of metals and contributing to corrosion and adhesion prevention of metals.

In this project, a picosecond laser machining system based on multi-beam parallel machining is developed, which can etch and machine various shapes on curved surfaces. The algorithm of conformal layout of superhydrophobic microstructure elements and the control software of laser etching process planning were designed, and a series of original intellectual property rights were obtained in the aspects of optical path design, beam transformation and diagnosis, workpiece calibration, process parameter control and test methods. Aiming at typical metal materials such as steel, titanium alloy and aluminum alloy for ship hull, the influence of the dynamic characteristics of beam energy time/space characteristic parameters on the precision of laser etching pattern, surface roughness and repeatability of etching effect was systematically studied, and the rapid construction mechanism of superhydrophobic/superhydrophilic surface roughness of different materials was developed. Mastered the relationship between the size and structure type of typical graphical microstructure prepared by laser etching and the micro-morphology of rough interface, anti-microbial adhesion performance, floating and drag reduction performance, and the control mechanism, and expanded the application research and development of super-wetting surface in floating and drag reduction performance, droplet adhesion behavior, controllable evaporation and concentration, underwater acoustic transmission characteristics regulation, deicing function microstructure, etc.

The project has published 27 academic papers, including 17 SCI/EI, 11 authorized invention patents, 13 master's degree training, 1 postdoctoral degree and 7 technology transfer. The mobile six-degree-of-freedom robot laser cleaner and the laser cleaning robot for the inner wall of pipeline developed by the project are being used in the need of paint removal and ice prevention of trainer skin of Civil Aviation Flight Academy of China, and automatic surface polishing of hardware sanitary ware (cylindrical workpiece) of Lingwei Innovation Intelligent System (Zhejiang) Co., Ltd.. Self-developed multi-beam parallel ultrafast laser projection precision etching equipment and supporting process software have been applied in Jiangnan Valve Co., Ltd., Shanghai Shangpu Optoelectronic Technology Co., Ltd. and other units, initially realizing the transformation from applied basic research to engineering application, and generating hundreds of millions of economic benefits.

图1 水珠从黑色金属表面滚落,经过改造的金属表面再现“荷叶效应”

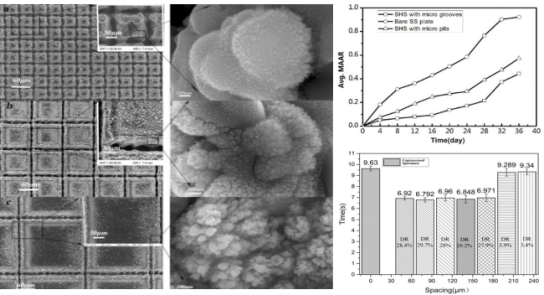

图2 超快激光制备金属超疏水微结构的抗微生物附着污损、壁湍流减阻特性